Limitations with Semiconductor Plastic Packages

July 2022

6 Top Benefits of Hybrid Microelectronic Technology

June 2022

Die-Level Semiconductor Programming

May 2022

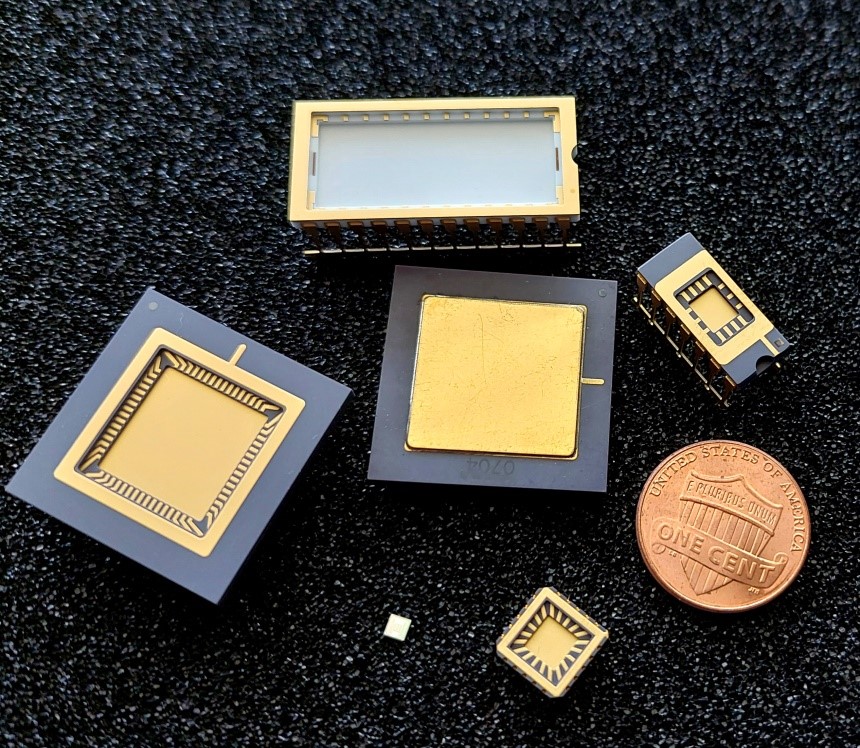

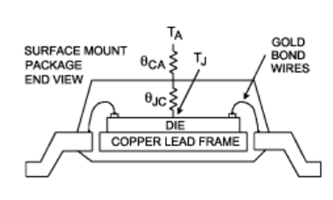

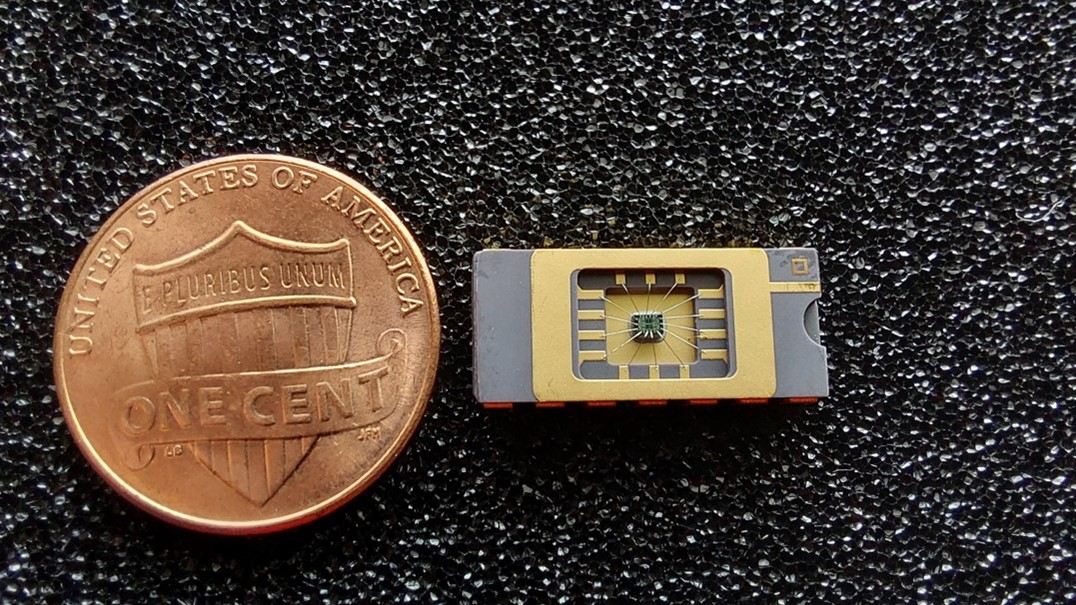

Field Programmable Gate Arrays (FPGA), EPROM, EEPROM, FLASH: Texas Microelectronics Corporation has the ability to program FPGA’s and most memory devices at the die level, before insertion into a package.

This process provides the distinct advantage of reducing the total packaged pin count to power and I/O lines only. The die’s programming pins need not be connected to the package itself unless your design specifically requires them. FPGA and memory die can be placed in various package pin counts dependent upon die size and your I/O count requirements.

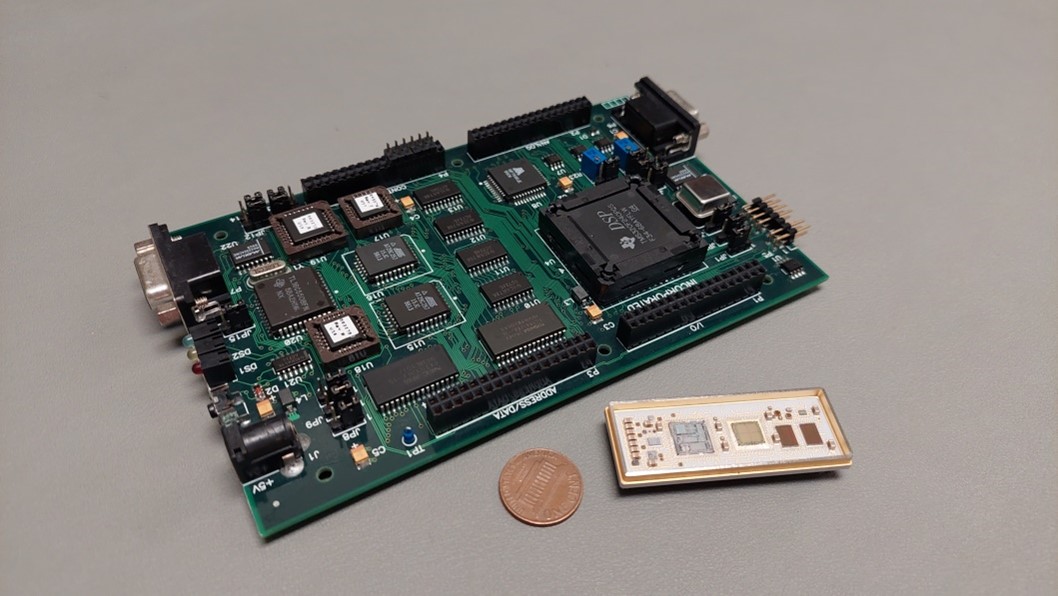

These designs may be packaged in a monolithic configuration or incorporated with other die as part of a true microelectronic hybrid circuit. For high density and mixed signal components, die level programming, with additional support circuitry can be utilized to provide a solution without redesigning your entire product.

Texas Microelectronics has been utilizing this technology for 2 decades, however recently we are seeing a significant increase in design requests for die programming and ASICs due to the worldwide supply chain shortages of traditional Commercial off the Shelf (COTS) semiconductors.

A programmed FPGA, or a dedicated ASIC can emulate other semiconductors therefore filling the supply chain gap, which enables our clients to continue to produce their products without interruption.

The Semiconductor Shortage – The 3 Why’s

April 2022

“Semiconductor shortage”. It’s a phrase that is becoming more common in our daily lives, and most of us are tired of hearing it. Unfortunately, it’s not going away any time soon.

As someone that comes from a semiconductor and electronics industry background, I’m going to share some insights as to the 3 main reasons for the shortage. While the reasons are multicausal, I’ll keep things simple for brevity.

It will come as no surprise to anyone that this sad story begins with the word, “COVID.” Let’s take a step-by-step chronological look at how we got into this mess.

First, when COVID first rose its ugly head, millions of people hid under their kitchen tables and wouldn’t even venture out of the house.

The first step in this mess is that car and truck sales plummeted. When this happened, the Procurement departments of the automobile manufacturers both cancelled and greatly pushed out orders for everything, including semiconductors.

Simultaneously, the consumer demand for items such as Big Screen TV’s, cell phones, Surround Sound Systems, and Laptops skyrocketed. The Procurement departments of these manufacturer’s then issued purchase orders for every semiconductor they could get their hands on.

And they got what they needed.

Fast forward to the first half of 2021 when the COVID vaccine became widely available. People rushed to get vaccinated, then slowly ventured back out and began to, yes, buy cars and trucks again. As the demand for automobiles increased, the Procurement departments of the manufacturers began to place orders for semiconductors again, and were told, - “So sorry, you’ll have to wait at least a year or more as we’re all booked up from other consumer demands.”

The consumer market for cell phones, TVs, and laptops, etc. consumed everything on the open market. It was a double punch to the semiconductor shortage. The above are the first 2 main reasons for the semiconductor shortage.

Make no mistake, the semiconductor manufacturers are running their factories 24/7. They are producing every device possible. New questions logically arise such as, “Why don’t they build more factories?”, to which the answer is, - they are, but it takes years to plan and build a sophisticated multi-billion-dollar semiconductor manufacturing facility.

Next, let’s talk about that third reason for the shortages, that has absolutely nothing to do with COVID.

For a moment, and for the sake of this discussion, let’s pretend that COVID never happened. Even without COVID, the overall demand for advancing technology in every market segment: automotive, appliances, consumer entertainment systems, etc. still moves froward, which automatically generates an ever-increasing demand for semiconductors.

This is the trifecta that is causing the world-wide semiconductor shortage. All indications point to a slow recovery. Don’t expect to see any significant relief in the semiconductor supply chain until at least late 2023.

OEM’s are going to have to get creative for the next couple of years until the shortages abate. As an example, automobile manufacturers, in order to sell the number of vehicles necessary to meet their financial minimums, will have to offer vehicles with reduced technology options, or in other words, offer more models as “bare bones” editions. Watch for it. It’s coming.

Here at Texas Microelectronics we’re seeing a significant increase in inquiries to develop and produce emulation devices to replace commercial semiconductors that are simply not available. We welcome the challenge.

|